Plot No. 5503/2 GIDC Vatwa, near Trikumpura cross road , Ahmedabad, Gujarat 382445 India

Fabrication Work started in 1982 By Hasmukhbhai A Solanki with workshop area 70 Square Meter at CTM, Ahmedabad. who had powerful imaginative strength, dreams and affluent skills to fulfill them.

Developed First Product Marking Machine for cable industry. Cable marking is a fundamental part of quality management. Cables are clearly identified by identification numbers. The products can then be traced and the installation of the cables made easier by being marked for their function or installation instructions.

With Good Progress in cable industry nilkanth engineering works started manufacturing Take off, Pay off and Caterpillar machines for Cable industry. Poly cab,Gujarat Telephone cable Limited and Bhagyalakshmi Industry were the reputed customers of our company.

Being an Indian company we have sound fundamentals and firm belief in good business ethics. We specializes ourselves into designing machines for easy operation, maintenance and economic performance. All the machines are designed giving priority to performance, maintenance, good machine life, great value for money.

Nilkanth Engineering Works start Manufacturing a Paver Finisher Machines for road construction projects.Our strength lies into our on-field experience and understanding the customer’s requirement and blend them with our knowledge for optimal and consistent output.

In 1995 we have started Asphalt Drum mix plant manufacturing.

We have developed this equipment to help contractors produce hot mix asphalt using discontinuous process with the help of accurate weighing technology coupled with fast, low maintenance and reliable mixer.We felts proud to be quality conscious andrefrain from compromising on quality even though faced tough competitions on prices. We always use standard quality material and keep ourselves updated with latest technology developments. We had team consisting a mix of well experienced and fresh engineers / technicians who are regularly trained and made acquainted with on-site reports.

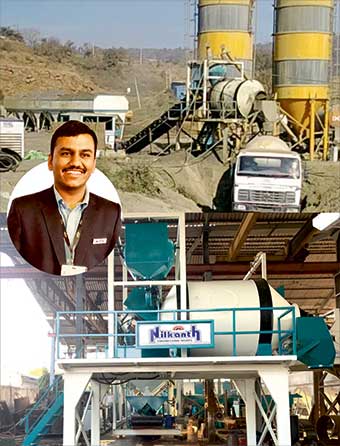

Established New Factory with 1500 Square Meter at Vatva GIDC,Ahmedabad and Nilaknth Engineering Works Enter in the concrete Industry, we have manufactured our first Mobile concrete batching plant at our new Factory. we have started supplying mobile concrete batching plant in Gandhidam, Bhuj , Kutch area. we have got great response from gujarat customers with our mobile concrete batching plant.

With Mobile Concrete Batching Plant we have developed Reversible Concrete Mixer for construction industries,Agro industries, Chemical industries, Ceramics industries, Ready mix plaster industries etc to mix different ingredients in accurate proportion. Our mixer is fabricated from heavy duty structure steel.

Reversible Concrete Mixer used for building construction and various constructions site compromises of accurate mixing with accurate calibration.

Added more Two Products in concrete batching plant range with improvements. Based on extensive research, of all our products the company has won acclaim for concrete batching plant performance and durability.

Started export of reversible concrete mixer and mobile concrete batching plant in Russian and african countries. Customers’ long-term trust in the brand is rewarded with repeated and reference clients for us.Customer Satisfaction is our motto & due to this Nilkanth have best reputation in market and got repeat & reference order from several customers.

The range of Compact Concrete Batching Plant in India is also extensive and the models are available in the vast range. We can’t imagine the task of construction on the roads, bridges, Canals and various other building projects without the help of batching plant. so we regularly introduce new updated concrete batching plant in different different model and capacity.

Transit mixer is a multipurpose device that used to transport concrete from a concrete batching plant. The transit mixer is loaded with dry material and water; The transit mixer consists of a drum with a spiral blade which has the ability to move in two directions.

Nilkanth has always pioneered in providing cutting-edge products like concrete batching plant and meeting the demands and needs that arise in the infrastructural development of the government and private sector. Nilkanth has made sure to keep meeting the expectations across diverse industrial segments by making use of the latest technology.

Nilkanth Introduce it's First Mobile Tower Cranes in 2014,which are used for civil construction Works, these are self-erecting / self-folding machines. These have provisions for built-in generators to provide electricity needed to operate the machines.With a rich experience in designing and developing customized engineering solutions with latest technology, today the company is one of the leaders in manufacturing of construction Concrete Batching Plant.Nilkanth Engineering Works is well-known for their customer relationship and serves their client with utmost satisfaction all over the globe.

Nilkanth gained Trust from existing customers and got order of 1st Nilkanth 120 Cu.M/hr from DC Gurubaxani Company and successfully installed Stationary Concrete Batching Plant with Sicoma make 3 Cu.M Twin-shaft Mixer at nagpur for Road Projects.

Nilkanth Introduce Reversible Concrete Batching plant with Capacity 1 Cu.M per Batch for Dam Project at parbati dam project site MP for our esteemed customer Laxmi Constrction, we have given total 2 plant of 60 Cu.m/hr with Reversible Drum for their MP Dam Projects.

Mr.Hardik Solanki joined Nilkanth in February,2018. He is the son of Mr.Hasmukhbhai A Solanki. He has done Msc in Engineering Business Managment From Coventry University,UK.He is responsible for sales,marketing & Service, dealer building,strategy planning,handling corporate customers in India and abroad. He has been Involved in developing exports of Nilkanth Engineering Works and has dream of taking the Nilkanth Engineering Works to global heights. His focus is on bringing in the finest technology products and expertise to the industry, with an aim to deliver complete and reliable solutions.

Introduced New Hightech Design of Mobile and compact concrete batching plant inline 3 BIN. As an expert and a one-stop solution for concrete batching plant, Nilkanth is moving towards the

cutting-edge advancement that provides high-quality components to add to the longevity,reliability, and durability for manufacturing the best quality Concrete Batching Plant.

with previous model modifications with the customer's demand Nilkanth Introduced Compact concrete batching plant in-line 3 Bin with TM Height.

With the advancement in technology, the future of India is rapidly changing when it comes to the construction industry especially concrete. Companies like Nilkanth have started embracing industry 4.0 by making a substantial investment in the new Factory of 22000 Square meter area at Varsola, Factory will be fully operational by 2022.