Plot No. 5503/2 GIDC Vatwa, near Trikumpura cross road , Ahmedabad, Gujarat 382445 India

There is a proverb, “Swords cannot replace Needles”. Type of mixer plays equal importance in choosing quantity and quality of concrete. Concrete is a mixture of cement sand and aggregate, Improper mixing can lead to heavy infrastructure losses and sometimes can claim the lives of people. Hence, it becomes utmost important to make sure that concrete is mixed properly and is homogeneous.

Problem of segregation and bleeding are ill effects of improper mixing of concrete. Things get complicated when we add admixtures as the quantity and mixing time of admixture governs the quality of concrete. Diligent choice of mixing type shall be made. We are here to give you insight on type of mixers and its uses so that it helps you to know which type suits your project the best.

The first mixer was invented in 1900 by T.L Smith which contained conical drum. It looks like primitive model of current drum type mixer. As and when time lapsed, with evolution of science and technology we now have 4 types of mixer in market.

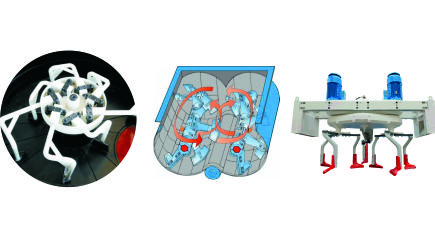

Pan Concrete mixer is used in most of the batching plant. There is a 7 arms for mixing and rotating equipment is attached centrally to it. There are mixing blades attached with Arms which helps in mixing the material properly. After mixing the concrete, there is a discharge gate through which the concrete is discharged.

Above figure shows a pictorial representation(plan) of Pan Type mixer used in batching plant. The batch capacity ranges from 0.375 -1 m3 per hour. The mixing time shall be adjusted but generally it is between 30 - 120 seconds. Pan concrete mixer can be used in construction of buildings, commercial complexes, and other cast in situ constructions. Pan Concrete Mixer is most common mixer in construction industry. It is used in small to medium construction activities. It can produce stiff and lean concrete mixes.

Twin Shaft concrete mixer are used wherein there is huge demand of concrete. The demand production of concrete is high and when one needs address huge pouring.

There are two shafts arranged horizontally and material is poured in them. These shafts rotate anti clockwise direction with several blades attached to it. The speed of mixing can be adjusted. The two shafts are connected with a Cardan joint.

Twin Shaft Concrete Mixer has high productivity, Low mixing time and high batch production. This results in quick dispatch of concrete with high quality and precision.

At nilkanth Engineering works we have inbuilt Twin Shaft Mixer and we also provide twin shaft mixer manufactured by Sicoma.

Planetary Concrete mixer is used for special concreting and precast concrete construction. It is widely used for dry concrete and colored concrete structures.

The mechanism adopted is like pan type, but difference is in mixing mechanism. Like the solar system, two flanges of blades are rotated about central axis, whereas in Pan mixer the rotating equipment is placed at central axis.

The capacity of batch ranges from 0.5-2 m3 per batch. Planetary Concrete mixer is easy to handle, and the mechanism is user friendly. At nilkanth engineering works, we provide planetary concrete mixer manufactured by Sicoma.

It is the oldest type of mixing mechanism since the inception of concrete. For construction of canal, dam or large scale bridges where coarse aggregate size above 50mm is used, Drum type concrete mixer is best suited.

Further on its advancement, few modifications in drum type concrete mixer have also been made like you can have reversible drum type concrete mixer, rotary drum type concrete mixer and so on.

A semi conical shaped drum is used for mixing material. It has blades inside the drum after adding material and mixing for brief period, one can discharge the concrete through its outlet. It is best suited wherein plumb concrete or concreting wherein higher size of aggregate is used. It is very simple user friendly, and it can be easily operated by semi-skilled labor.

We aim to provide best solutions by imparting excellent knowledge with honesty and integrity. Our aim is to minimize error of choosing concreting options, resulting in optimized project cost. Prudent choice in development today can lead to sustainable future.